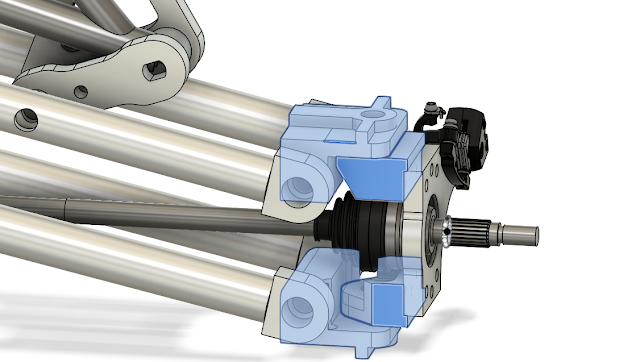

With an assist from Andee, we assembled the new suspension system for the Aluminum Falcon!

Nice, right? I spent most of a week preparing for the effort by test fitting one side to determine the number of bolts, nuts, and bearings needed to complete the assembly.

After I cut lengths of 1/2-inch and 3/4-in threaded rod for attaching parts together and drilled holes into the chassis to connect the fulcrum brackets, I discovered two design fails that needed to be corrected before I could assemble the suspension, both related to the hangers.

Each hanger is made from a couple of tubes connected by two bars, forming an "H". The problem with the inside hanger was that a crossbar on the chassis prevented installation. The problem was there the whole time and I just didn't notice it.🤦🏽♂️ Or I noticed it and forgot. Whatever. Look out the window.

Luckily, it was easy enough to fix. I cut a slot out from the lower tubes that was both wide enough to get around the chassis crossbar and installed additional bearings into the newly revealed holes.

The outside hangers had a different interference issue. We needed the attachment plate on the lower leg of fulcrum bracket to fit through the hanger, but the attachment plate was too big.🤦🏽♂️

To fix this issue, I used a bandsaw to trim down the length and width of the attachment plates to fit within the "H" of the hangers. I then used an angle grinder to round the corners to clear the welds on the hangers.

I turned the sleeve bearings down to size using the lathe. That was easy enough to do. The flanged bearings were not as easy. They were impossible to hold in the lathe because the flange stuck out like the rim of a top hat. Instead, I had to use the mill, but holding the flange in the vice was still tricky to do.

Because bronze is soft, it deforms if you squeeze too hard but the vice needs to be tight enough to hold the part while it was machined. I turned two round bearings into eggs finding that out. To avoid ruining more bearings, I made soft jaws out of plastic. The plastic is softer than bronze, so it got squeezed instead of the bearings.

This allowed me to hold the bearings more tightly without damaging them.

Once the stop nuts, washers, custom bolts, and bearings were ready, I made assembly kits for each side.

After days of preparation, Andee and I got to work assembling the new suspension.

The last piece of the suspension system--that holds the whole thing together and makes it all work--was a heavy-duty tension rod that connects the two lever arms. After a healthy dose of WD40 on the threads, I attached the rod.

Spinning the turnbuckle in one direction pushes the levers out, lowering the chassis into race mode. Spinning in the other direction pulls the levers in, raising the chassis six inches to get us through the mud and water.😎